Simulation of a VR industrial hall for testing the 5G network

Helmut Schmidt University is using state-of-the-art technology to test the potential of 5G networks in a realistic environment.

As part of the dtec.bw project DS2CCP at the Helmut Schmidt University, we have created a virtual industrial hall in Unity that simulates the conditions of the HSU’s 5G network and depicts various industrial scenarios.

The DS2CCP project is developing a digital Sensor-2-Cloud Campus platform that enables secure, wireless networking of sensors and actuators in industrial automation.

This includes the use of technologies such as IO-Link wireless and 5G to ensure reliable communication from the store floor to the cloud.

The project focuses on safety and timing requirements and provides a testing ground for research and industry collaborations.

This project is headed by Prof. Dr. Gerd Scholl at the Chair of Electrical Measurement Technology.

Integration of real emergency stop systems

In the VR industrial hall, machines can be deactivated using a real emergency stop switch.

The switch is worn on the body by users and its signal is sent via IO-Link Wireless (IOLW) and OPC UA over 5G to our software erPUB .

This then communicates with the Unity application on the VR headset (Meta Quest), enabling realistic and direct interaction between the virtual environment and physical safety mechanisms.

Use of the Meta Quest VR glasses

The Meta Quest Pro and Meta Quest 3 were chosen for their high computing power, excellent graphics quality and standalone functionality.

These VR goggles do not require an additional PC or external sensors, which significantly increases mobility and flexibility.

Easy integration with Unity and the ability to run content directly on the goggles made the Meta Quest the ideal choice for this project.

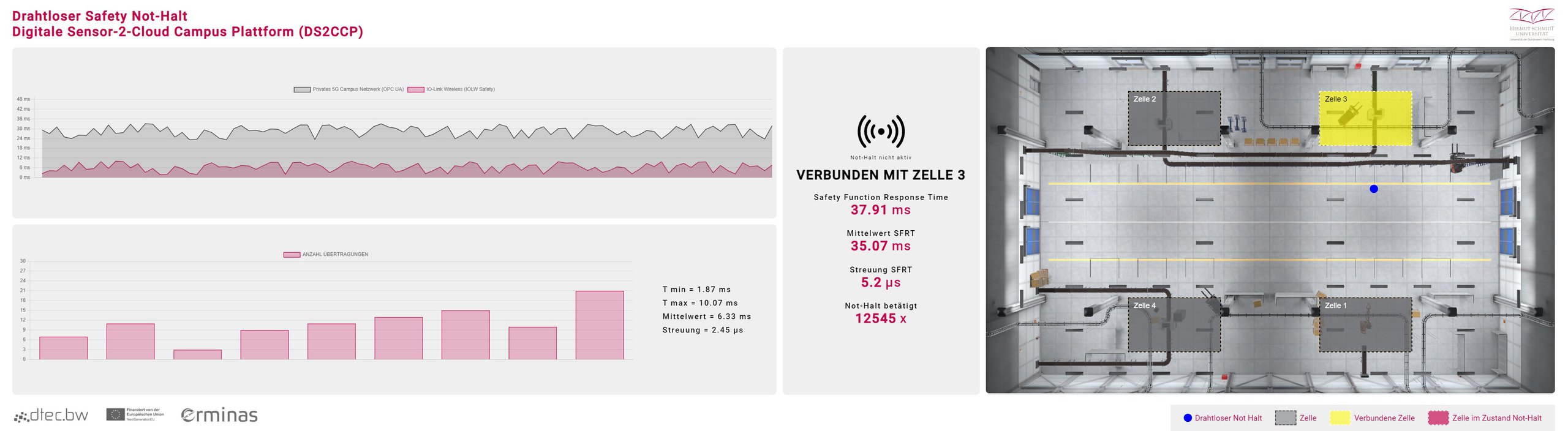

Comprehensive monitoring via dashboard

We have developed a customized dashboard for monitoring the VR environment.

It provides detailed insights into network communication by visualizing the latency times of the 5G network, the number of transmissions and the connected network cells.

On the right-hand side, a map of the industrial hall shows the live location of the person moving around the hall with the VR headset.

This near real-time data enables precise analysis and optimization of the VR experience.

The VR project demonstrates the practical application of 5G technology and shows how virtual simulations can be used to train and optimize industrial processes.

The dtec.bw – Center for Digitization and Technology Research of the Bundeswehr – is a scientific center jointly supported by both universities of the Bundeswehr and part of the German government’s economic stimulus program to overcome the COVID-19 crisis.

It is subject to academic self-administration.

The funds with which dtec.bw was endowed are used at both universities of the Bundeswehr to finance research projects and projects for knowledge and technology transfer.

dtec.bw is funded by the European Union – NextGenerationEU .

More references

You have questions about our projects?

We will be happy to advise you on our solutions and products and their use in your company. We look forward to hearing from you!