The first steps towards digitization are taken only hesitantly by many SMEs, but also by larger companies. This can lead to a development standstill, especially in established and well-running traditional companies: “Everything is going so well right now! Why should we change production now? Why do we have to start digitization now?” When everything is going well is the best time to maintain your existing advantage over your competitors. Here are five points on how to get started.

1. in the beginning there is curiosity

Everything is going well in your company: The machines are stable, production is running smoothly, the employees are well-coordinated and satisfied, and the figures are also right? Great, congratulations! Now is the best time to be curious about the digital future. Because there is still room for improvement: digitization can open up potential that was previously not even visible. It is often enough to turn just a few digital screws to open up new avenues and harvest data, for example. This is because data can be used both to optimize processes and to develop new business models. And no machines need to be replaced for this data harvesting. Be curious about the possibilities of retrofitting your existing machines digitally. Because there is more potential in your company than you can possibly imagine.

2. Analysis: Tapping potential through digitalization

Digitizing a company does not mean throwing everything that works well overboard. Digitization means redefining everything that works well through digitalization. And to open up new avenues that have perhaps not yet been considered. The first step is to analyze the processes. And every boss can do this themselves with their employees: Where do we lose time? Where are the routes too long? But also: What data do we want to harvest? Where could we harvest data? What could we do with it? In every company, there is a need for optimization that could not previously be achieved in an analog way. Even small initial steps towards digitalization can provide major new solutions.

3. take time for a creative exchange of ideas

It’s best to think together. It is not always the IT and technology experts in the company who come up with the right ideas. Get employees involved in joint brainstorming sessions who look at the company from a different perspective with creative thinking. Employees from partners and customers can also provide valuable impetus in a joint digitalization think tank, which can lead to completely new projects and collaborations. Also collect approaches that are not obvious at first glance or that cannot be solved easily. The best ideas for the first steps towards digitalization often emerge from initial rough drafts.

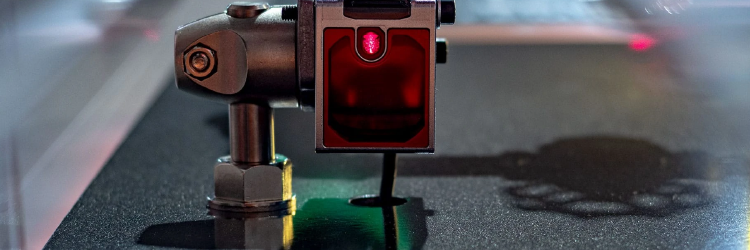

4. get IIoT and retrofitting professionals on board!

Initial ideas and considerations have been gathered and now you don’t know what can be implemented and how? This is the right time to bring experienced digitizers on board who are familiar with both the necessary software and the adaptation and design of hardware. Needs and feasibility can be analyzed in joint workshops. And with the help of design thinking and rapid prototyping, initial drafts for possible solutions can be presented quickly. On this basis, far-reaching and forward-looking decisions can be made with confidence, setting the course for gentle and sustainable digitalization.

5. prioritize - and get started

It may or may not start with machine learning, big data and artificial intelligence. Just get rid of paper processes at the beginning. Lengthy and error-prone paper processes still cost many companies a lot of time and effort – and constantly growing analog storage space in the form of folders and shelves. The paperless office not only saves space and many work steps: it can form the best basis for a long-term sustainable digitization process. Data obtained from production can be used efficiently here. Statistics and analyses quickly show the most sensible next steps in your company’s digitalization process. Another approach is to focus on predictive maintenance: If your systems can precisely predict when they need to be serviced, you gain a high level of planning reliability for your company and your partners.

Conclusion: Digitization does not mean turning the entire company upside down

Digitization does not have to be a hard cut that completely turns a company upside down. With well-measured and long-term first steps, it becomes clear which paths into the digital future are the safest and most efficient for your company. If everything is going well, the path to digitalization can be approached in a relaxed and focused manner.

But sometimes things just have to go a little faster. If a supplier breaks away and with it a familiar business model, it is important to get creative quickly and call in a digitization task force for help. We will talk about this in our next article.