The Revolution Pi from Kunbus is a small industrial controller for DIN rail mounting. With a whole range of IO and bus modules, the Revolution Pi – or RevPi – can communicate with all standard analog and digital sensors, actuators and bus systems as well as with TCP-IP-based networks. The RevPi contains a Linux computer, which makes it an amazingly versatile problem solver.

Revolution Pi: The all-rounder among PLCs

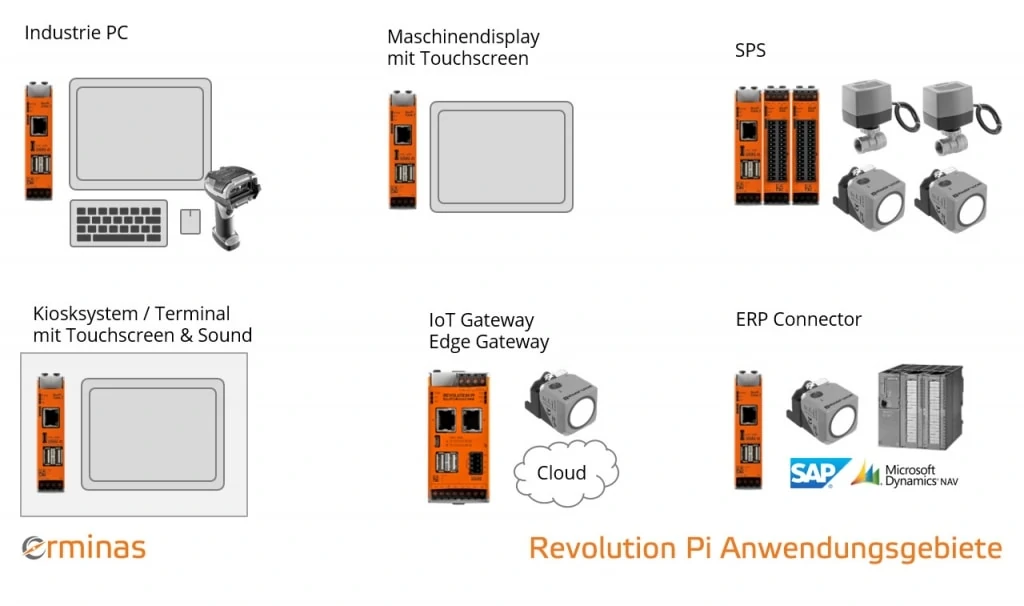

Im Gegensatz zur klassischen Speicherprogrammierbaren Steuerung (SPS) gibt es bei der Soft-SPS nicht die eine vorgegebene Software, mit der eine Programmierung vorgenommen wird. The Revolution Pi can be programmed in almost any language: High-level languages such as C, C#, Java, PHP, Python, with classic automation solutions such as Codesys, or with graphical tools such as NodeRed. This is where the huge potential lies: you can run almost anything on the RevPi. We present five possible application scenarios in this article.

1. Revolution Pi as a data supplier for ERP, BDE and PPS

What if your ERP, BDE and PPS systems could be automatically fed with data from production, eliminating the need for tedious and error-prone manual data entry? The Revolution Pi gives you access to your system data. You can use the RevPi as a system controller, retrofit your systems inexpensively with the RevPi and sensors or read out data from the existing PLC via Profinet, ModBus RTU or OPC-UA. If necessary, prepare the data on the RevPi before passing it on to your ERP system (e.g. SAP or MS Dynamics Nav), your production data acquisition system (PDA) or your production planning and control system (PPC). Both programming languages and most software solutions provide ready-made libraries and interfaces for REST, XML, JSON and for Excel and CSV exports. Incidentally, the data can run in both directions. The RevPi also provides you with order data from ERP or PPS directly at the machine.

2. Revolution Pi for modern system monitoring

Systems must be running. If this is not the case, it is necessary for staff to react quickly and, in the event of major technical problems, for external service providers to be organized quickly. With outdoor systems in particular, failures and faults are often detected late or reported late or imprecisely by the operating personnel. The Revolution Pi also helps here. Connected to the existing network or equipped with a mobile router, the Revolution Pi monitors the system. You can use any server monitoring software available for Linux or use erMON, a solution developed specifically for the Revolution Pi. Alternatively, you can also choose a cloud-based solution to which the Revolution Pi can send its data. You can now view the status of your systems, the fault history and statistics at any time via the browser on your PC or smartphone. Depending on the solution used, you will receive alerts via SMS, email, fax or messenger. This means that any malfunction is quickly identified and quickly rectified.

3. Revolution Pi as EDGE gateway in the DIN rail

Companies with many small locations in particular do not operate a data center with IT staff at every location. Nevertheless, data is to be collected from several systems, which can then be analyzed across locations on the company’s own servers or in a cloud solution. Here too, the Revolution Pi offers the solution. As the central remote station, this is where the data from all systems comes in: Via OPC-UA, ModBus, Profibus, Profinet, CANbus. Data is securely stored temporarily, pre-processed or transformed if necessary and then forwarded to the company’s own servers or cloud solutions via the Internet.

The Revolution Pi has the advantage that the Raspberry Pi (or more precisely the Raspberry Compute Module) forms the technical basis of the RevPi. There are countless free software libraries for data transformation for the Raspberry Pi, and every well-known cloud provider offers interfaces and tutorials for the Raspberry Pi that can also be used directly with the RevPi.

4. With the Revolution Pi, your systems come to the app

Do you develop and sell systems yourself? What if your system was available with a set-up and operating app for tablets and smartphones, and if the HMI (Human Machine Interface) of your system ran in the browser? Your customers would be able to access the system data securely from anywhere. Your service team would be able to connect to the system live before traveling to the customer, view error logs and use remote analysis. Your system supplies data to third-party systems via interfaces. All from a single source, just as we are used to from the consumer electronics sector. Your own Industrial IoT product line is easy to implement with the Revolution Pi.

5. Revolution Pi as digital twin of your system

While a production plant is in operation, it can only be tested and expanded to a limited extent. If the control program has to be renewed or expanded, the system is shut down or the work is done on an open heart. And what exactly you can test depends on the requirements of production on the day in question. The solution is simulation software, but this is usually only available for large and expensive PLC solutions.

The Revolution Pi with erTRACE software is an efficient and easy-to-use solution. From the point of view of your PLC, the machine consists of inputs via which signals come in. With erTRACE you can record the digital and analog inputs as well as the inputs of many bus systems. This allows you to create a library of recordings of different usage scenarios or record error scenarios on the running system. The Revolution Pi can not only record, but also play back for your PLC. The RevPi is now your system – only in pocket format. You no longer develop at the machine, but comfortably and efficiently in the office. Play those scenarios as often as you want. You can also download recordings from production remotely and thus reproduce and analyze reported faults. This is what the Revolution Pi does with erTRACE as the virtual twin of your system.

Revolution Pi at a glance and in use

The Revolution Pi is the Swiss Army knife for digitization

The Revolution Pi is a versatile soft PLC based on the Raspberry Pi. It has robust, industrial-grade peripherals and is reliable and cost-effective. The compact industrial PC can be expanded in a variety of ways with compatible digital and analog I/O modules and fieldbus gateways using the individual base modules, depending on requirements. The basic RevPi Core, RevPi Core 3 and RevPi Connect modules already have USB, Ethernet and HDMI connections. It can also be used to control machines. All this makes the Revolution Pi the Swiss Army knife of industrial PCs.