Every day, delivery bills, freight invoices and Excel spreadsheets pile up at our customer. The management remembers the days when freight costs were entered manually into different systems – a tedious routine full of errors and delays. An incorrectly recorded weight or an overlooked item not only meant lost money, but also stress and lost time in the monthly closing. But this is exactly where digital change comes in: Modern ERP systems such as Microsoft Dynamics 365 Business Central, combined with data from IIoT (Industrial Internet of Things) platforms such as erPubpromise a remedy. They automate freight cost processes, making them more efficient and virtually error-free.

In this article, we take you on a journey through the digitalization of freight costs. We highlight the typical challenges faced by small and medium-sized logistics companies (SMEs) and tell the story of our customer, a company that has taken the step into the digital future. Find out how the integration of Dynamics 365 Business Central (BC) with the IIoT platform erPub builds a bridge between warehouse and software – and what tangible benefits this brings for decision-makers and management in the logistics industry.

Challenges: Managing freight costs in the analog age

Freight costs are an opaque item in many companies. The weights and dimensions of shipments are often recorded manually, freight rates are transferred from PDF files and invoices are later manually compared with orders. These analog processes are error-prone and time-consuming. Errors – be it a transposed number or an incorrect rate – cost money and add up. In addition, many companies pay excessive freight costs because there is no overview in day-to-day business and incorrect calculations remain undetected. The consequence: profits shrink and controlling lacks the necessary cost transparency.

But it’s not just about money. Manual data entry ties up human resources that are lacking elsewhere. Employees spend too much time typing up delivery bills or copying figures from emails. Sales and logistics teams lose a large part of their time just for preparing quotations and entering data – time that is lacking for strategic tasks or customer service. Added to this is the sluggishness of the processes: Days or weeks can pass between goods issue and the actual posting of freight costs. During this time, errors cannot be proactively corrected, complaints pile up and the flow of information along the supply chain comes to a standstill. Without up-to-date data, warehouse logistics lacks information on the status of shipments and management has difficulty obtaining ad-hoc information on freight charges. In short, manual freight cost management is a drag – it causes avoidable costs, harbors risks and represents a real competitive disadvantage.

The way out: integration of ERP and IIoT as a solution

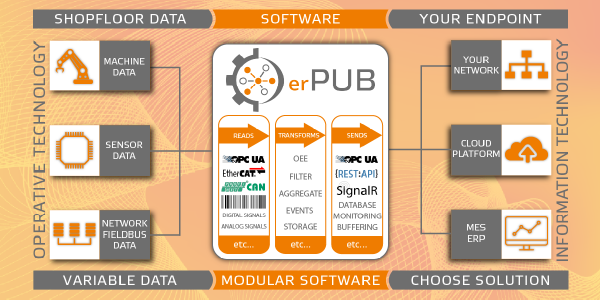

So how can this dilemma be resolved? The answer lies in networking IT and OT (operational technology) – in other words, linking modern business software with data from the physical world. Microsoft Dynamics 365 Business Central (BC) as an ERP system digitally maps business processes from financial accounting to warehouse management. However, the system only really comes to life when Industrial Internet of Things (IIoT) data is connected. IIoT means that devices and sensors automatically send data in real time. In logistics, IIoT can be used for a variety of purposes – for example, to track parcels or count stock levels in real time. Why not use this data directly in Business Central to control processes and make decisions?

This is where erPub comes into play – an IIoT platform that builds precisely this bridge. erPub was developed to connect operational technology (OT) such as machines, scanners or sensors with IT systems such as Business Central. The platform collects and processes data decentrally from the lowest machine level right up to the software. And best of all: erPub can be scalably, securely and flexibly integrated into almost all existing networks – whether new installations or existing systems. In other words, erPub acts as an interpreter between the IIoT device in the warehouse and the ERP in the cloud. Weight sensors at the loading ramp, telematics units in trucks or RFID scanners in the warehouse send their information to erPub, which bundles the data and forwards it to Business Central in real time. The previously static processes become dynamic: data flows automatically without employees having to pick up the phone or enter values manually.

The advantages of this integration are obvious. Automation drastically reduces manual work. Not only are personnel costs reduced, employees can also devote themselves to other tasks. In particular, data quality is improved: the direct transfer of data from scales, scanners and vehicles to BC eliminates the source of human error. In addition, the data is forwarded to BC promptly. Freight costs can now be booked as the truck rolls out of the yard, rather than days later. This speed and accuracy makes companies more agile and gives them a clear competitive advantage.

Practical example: Digital freight cost control through IIoT integration

Our customer, a medium-sized freight forwarding company, has successfully digitalized its freight cost processes – with measurable economic benefits. By connecting the trucks’ GPS and sensor data to Microsoft Dynamics 365 Business Central, transport data is now recorded in real time and automatically assigned to the respective orders. This allows shipments and freight costs to be tracked seamlessly and on a daily basis.

Before digitization, the process was very manual: shipping weights were determined on a floor scale, noted by hand on delivery bills and then transferred to Excel. This approach regularly led to transposed figures, incomplete information and time-consuming checks in the accounting department. The freight invoices from the service providers often only arrived weeks after delivery – a time-consuming and cost-intensive challenge for the entire company.

“We constantly had small deviations – sometimes five kilograms here, sometimes a transposed number there. Over the year, this cost us thousands of euros and tied up an enormous amount of resources,” recalls the management team

With the introduction of IIoT tracking, this problem is now a thing of the past: Weight data, location information and proof of delivery now flow automatically into Business Central. This means that freight costs are calculated immediately, displayed transparently and can be analyzed in real time. The result: higher data quality, less administrative work and a significant reduction in incorrect bookings.

Together with us, our customer decided to migrate to Microsoft Dynamics 365 Business Central and use the new IIoT integration platform erPub in parallel. The migration was carefully prepared: First, all master data – customers, articles and tariffs – was consolidated in Business Central to create a centralized and consistent database. This was followed by the digitalization of the physical processes.

Networked industrial scales were used in the warehouse and the forklift trucks were equipped with robust tablets that drivers can use to record shipments using barcodes. The company’s own fleet of trucks was equipped with IIoT devices for GPS tracking and for recording important characteristics such as load status and temperature – particularly relevant for temperature-sensitive goods.

All of these devices now continuously send data, which is seamlessly transferred to the ERP system via erPub. Standardized interfaces and APIs ensure that the IIoT data points are available in Business Central in real time and are automatically assigned to the corresponding orders and shipments.

The effects became apparent practically overnight. Today, when an order is picked, the scales automatically record the pallet weight and transfer it directly to Business Central. There, the freight costs are calculated immediately based on the stored rates. The responsible dispatcher sees the shipment in the dashboard and knows where the goods are at all times thanks to IIoT tracking.

If a truck is stuck in a traffic jam or deviates from a planned arrival time, the system automatically sounds the alarm – proactivity instead of reactivity. The benefits are also clearly noticeable in accounting: freight invoices from external logistics service providers are now read in digitally and automatically assigned to the appropriate deliveries by the system. Business Central checks whether the invoiced weights and routes match the IIoT data.

Incorrect invoices are now a thing of the past. And if a value is incorrect, Business Central provides an immediate notification – and the team can react immediately. This not only saves time, but also reduces freight costs.

It used to take several days at the end of the month to allocate and check the freight costs for a week’s tours. Today, this process runs largely fully automatically in the background, while day-to-day business continues undisturbed.

Employee acceptance is also high. What initially sounded like a major upheaval turned out to be surprisingly intuitive in practice. The drivers are delighted because they no longer have to fill out forms – they scan the order and everything else runs automatically in the background.

The solution has also been well received by the administration: Thanks to the transparency, employees can always see in the system which freight costs are assigned to which order.

This example impressively demonstrates what concrete digitalization can look like when the right tools are intelligently linked together.

Tangible benefits: Automation and error avoidance for freight costs

Our customer’s story is not an isolated case. More and more medium-sized companies are recognizing the benefits of automation in logistics – especially in such cost-intensive processes as freight cost management. But what exactly are the business benefits? Here is an overview of the key benefits of integrating Business Central with IIoT data (via erPub):

Less manual work, more efficiency: routine tasks are carried out digitally so that employees have time again for value-adding activities. Processes that used to take hours or days (e.g. calculating prices, transferring data) now take minutes or seconds. Logistics teams can concentrate on exceptions and planning instead of entering data manually.

Error reduction and cost savings: Automated processes almost completely avoid input errors. The quality of the data increases, which has direct financial effects – overpayments and miscalculations are avoided. Your company only pays for what is actually incurred and thus achieves a better margin.

Real-time transparency: All relevant information is available immediately and centrally. Questions such as “Has delivery X already been delivered and what did it cost in freight?” can be answered with just a few clicks. Management and scheduling make decisions based on up-to-date, reliable data instead of analog lists.

Proactive action through live data: Thanks to IIoT, you always know where your consignments are and what condition they are in. The system automatically detects irregularities – such as delays or deviations in weight. You can inform customers or intervene before a problem arises. This strengthens trust and customer loyalty.

Integrated platform & scalability: The combination of Business Central and erPub fits seamlessly into existing IT landscapes. Both systems are scalable – new warehouse locations, additional sensors or changed tariffs can be flexibly integrated. The result is a future-proof infrastructure that grows with your company.

Concrete implementation: Dynamics 365 Business Central meets erPub

After all the advantages, the crucial question is: How time-consuming is the implementation in practice?

The good news: With experienced partners and modern tools, an integrated solution can be introduced quickly and efficiently – often much faster than many expect.

Microsoft Dynamics 365 Business Central is a cloud-based ERP platform that is specially tailored to the requirements of small and medium-sized companies. It offers extensive configuration options – for example, to manage freight costs as a separate cost category, to store freight rates or to set up automated workflows for invoice control.

Many functions are already available out of the box, such as the recording of purchasing and sales costs or the distribution of surcharges to items. The Business Central standard also provides for freight costs to be calculated during order entry and later allocated to the actual invoices – a solid basis on which further automation can be built.

The integration of erPub as an IIoT connector requires careful planning. Together with erminas as the implementation partner, the specific use cases are first defined: Which data points should be integrated?

In the case of our customer, this included pallet weights, vehicle locations and temperature data. Other companies could integrate container fill levels, machine operating hours or access controls at loading ramps – erPub is extremely flexible here. The concept phase is followed by the technical implementation: the required hardware – sensors, trackers, scanners and similar devices – is installed or integrated via existing interfaces. erPub itself runs as a Docker container on an edge device or server on site or in the cloud and communicates directly with Business Central. Data is transferred to the ERP system in real time via secure APIs. A key point here is that data sovereignty remains entirely with the company. erPub acts as a data intermediary, not as an external cloud service that stores sensitive logistics data. erPub can be seamlessly integrated into existing networks, meaning that no systems need to be replaced and no long downtimes need to be accepted.

The technical setup is followed by the test phase: test deliveries are simulated, sensors are triggered in a targeted manner and the results are checked in Business Central. Key users from the specialist departments should be involved at an early stage to ensure that the solution works in practice and meets real requirements. Targeted training ensures that all employees understand the new process. Thanks to Business Central’s intuitive user interface, familiarization is easy – any reservations quickly disappear.

One aspect that is often underestimated is data cleansing in advance. It ensures that all master data is correct and up-to-date – such as the dimensions of all items and the assignment of suppliers and carriers. The cleaner this data basis is, the smoother the automatic booking and allocation of freight costs will work later on.

Once the system is live, the added value is immediate. It is important to understand digitalization not as a one-off project, but as a continuous improvement process. Both Business Central and erPub offer regular updates and a wide range of expansion options.

In future, it will be possible to integrate additional IIoT data sources, such as telemetry from production machines or AI-supported route optimization. The platform is already prepared for this. Thanks to the close integration with Microsoft Azure and other cloud services, even predictive analytics scenarios that still seem visionary today can be realized.

However, even in its basic function, the solution offers enormous potential for automation, transparency and error prevention. Companies can scale the scope individually – from connecting a single digital scale to a comprehensive Logistics 4.0 infrastructure.

Conclusion: Digital now - the competition never sleeps

The integration of Microsoft Dynamics 365 Business Central with IIoT data via erPub impressively demonstrates how logistics and freight cost management can be rethought in the digital age. Automation and networking are transforming formerly slow, error-prone workflows into lean, highly transparent processes.

companies – such as our customer’s forwarding company – are already benefiting from time savings, cost savings and unprecedented transparency. You can calculate more precisely, invoice faster and react proactively to events.

In short, you gain control over an area that used to be notorious for unpredictability.

This is a great opportunity for decision-makers in medium-sized companies. Those who opt for digital freight cost processes now will give their company a decisive head start. The technologies – from ERP systems to IIoT platforms – are now mature and proven.

The risks and entry hurdles are manageable, while the return on investment is clearly measurable: faster processes, fewer errors, more satisfied customers and employees. And last but not least, the certainty of not being left behind by the competition – because companies that stick to manual processes will fall behind their more agile competitors in the long term.

The success factor of the future is data – its availability in real time and its intelligent use. The combination of Microsoft Dynamics 365 Business Central, erPub and IIoT technology creates the basis for precisely this. This keeps decision-makers and managing directors at eye level with digital development – without having to be IT specialists themselves.

Now is the time to set the course.

Put an end to paper chaos and uncertainty – and lead your company into a more efficient and error-free future of logistics with automated, integrated freight cost processes.