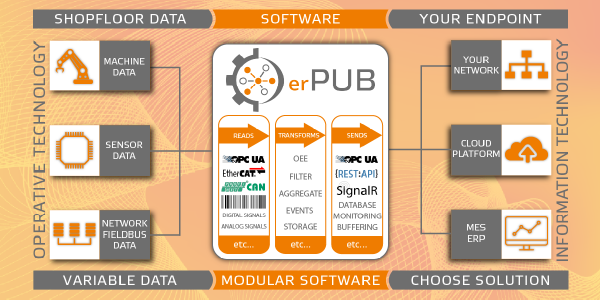

erPUB - The bridge between OT and IT network

With erPUB, data management is achieved decentrally from the lowest machine level to the highest IT level. And the best thing about it: erPUB can be integrated scalably, securely and flexibly into almost all existing networks, regardless of whether they are new or existing systems.

The right package

for every company

erPUB can be used on a monthly subscription basis or purchased. You have a special use case? During a meeting, we can take your requirements and adapt erPUB to your needs.

erPUB subscription

- Deployment as a Docker Container

- compatible with your software

- try for free

- 12 months running time

Buy erPUB

- Deployment as a Docker Container

- compatible with your software

- try for free

- Adaptable to your needs

The price of the erPUB subscription depends, of course, on the number of licences required. The more licences you need, the cheaper erPUB becomes! Need more information about erPUB? We have provided you with all the technical information separately.

Use of erPUB: Example in production

erPUB is the ideal tool for extracting data from your production and making it usable.

erPUB can be integrated into almost any network thanks to its high flexibility and can be run on an edge device, server or directly in the machine on an industrial PC.

This enables you to make your production more transparent, effective, value-adding and future-proof.

production without erPUB

- no overview of the actual utilisation

- increased error rate and few clues

- decreased machine availability

- sudden breakdowns and machine failures

- unnecessary costs for investments

- existings data remains useless

- increased complexity in asset management

- extensive and error-prone Excel tables

production with erPUB

- View the current status of machines from anywhere

- OEE calculation and visualization for direct data conversion

- Benefit from optimized and faster production

- Reach the maximum potential of your machines and benefit from improved quality

- Reduce material, production and energy costs

- Get an overview of the machinery

- Compare the condition of machines before and after maintenance

Frequently asked questions

You have questions about erPUB? We will gladly try to provide you with some information. Maybe your question is already answered. Otherwise, you can of course contact us at any time.

erPUB is a modular software platform for the automatic acquisition, integration and publication of machine data – specially designed for industrial environments in which sensor and process data must be efficiently transferred to existing software systems. The data can be directly pre-processed, filtered and combined with other information. This means that only relevant data is transferred to the connected systems, which relieves the network and reduces costs.

erPUB is ideal for:

Mechanical engineering & Industry 4.0

Manufacturing companies with a heterogeneous machine landscape

Logistics processes

Companies with a need for predictive maintenance, production monitoring or quality analyses

erPUB connects machines via various protocols such as OPC UA and processes:

Analog and digital sensors

Industrial interfaces (OPC UA, MQTT)

Formats: JSON, XML, CSV

Cloud destinations such as Azure or AWS

An example: erPUB runs on a RevPi and reads measured values such as temperature (RTD/PT100) and speeds. If the temperature exceeds a defined value, depending on the speed, a message is sent to another system for further analysis / machine learning.

Example “Temperature Machine Learning → Azure”:

Automatic recording of temperature data via PT100/PT1000

Pre-processing and ML-based pattern recognition

Publication of data in Azure IoT and analytics services

This creates real-time predictive maintenance scenarios – real-time monitoring paired with AI

Connection via OPC UA, MQTT or RevPi as an edge device

Data is provided with open APIs for ERP, MES, BI and cloud

Standardized data preparation and storage enable simple further processing

erPUB runs on Linux, Windows and macOS systems, either natively or as a Docker container.

The configuration of erPUB can simply connect existing modules as required and thus be easily configured as a no-code solution.

You can also develop your own data inputs, processing and data outputs. These can be integrated directly into erPUB in .NET or connected via interfaces (e.g. Python programs or Docker containers).

Standardized data integration across heterogeneous systems

End-to-end solution: from data capture to pre-processing and publication

Scalability: from single machine to factory network

Transparency through central administration

Secure data transfer via TLS/HTTPS

Rights and user management for internal access

Versioning and history for data traceability possible

Can be run on your own systems without access to the Internet or network

Edge device (e.g. RevPi, Beckhoff PLC, Windows terminal, Raspberry Pi, …) for data acquisition

Sensors for data acquisition as required

Mobile radio router for stand-alone systems

Quick start with preconfigured modules within hours to a few days

Concrete pilot configurations based on your data can be realized at short notice

Modular design – from proof of concept to fully integrated smart factory solution